When technology and human mind shake their hands with each other, be ready to invite a baby innovation to work in the interest of society. Yes, this statement is very true as technology has all the power which can be properly applied by the talented human brains to gift the world with wonderful innovations.

With one such gift, here is the galvanized product that has become a great help to the people indirectly as it safeguards them with unforeseen electric accidents. With the galvanize process, the wires are made safe avoiding any sort of mishap to occur. There is a full-fledged process known as hot dip galvanization carried out in order to cater these security and safety reasons. Let us know more about the entire galvanized structure available with one of the popular suppliers, Tanya Galvanizers that enables these security solutions.

The sub-station structures i.e. an assembly of equipments that support the main galvanization processes are:

- Post Insulator

- Lightening Arrestor

- Beam

- Current Transformers

- Power Transformers

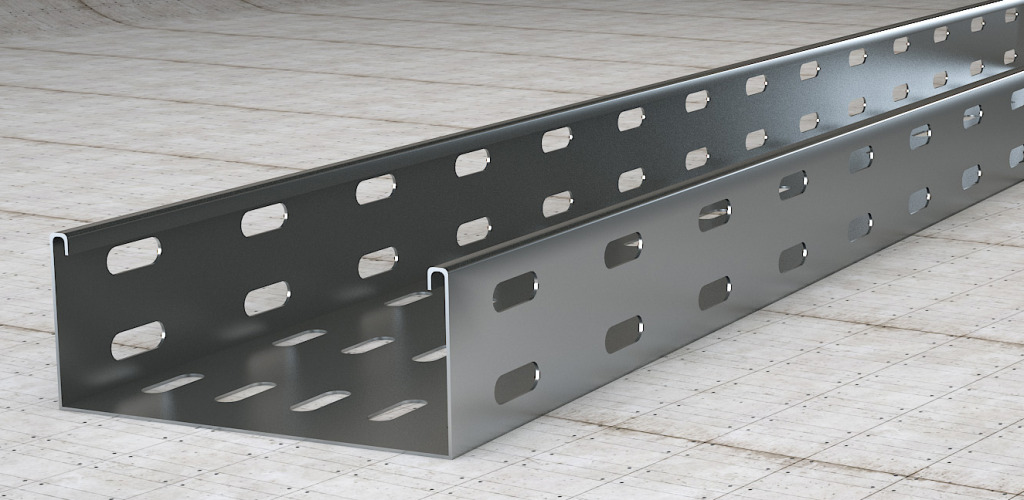

The motive of having Sub-Station Structures is to support power grid components and other electrical equipments. The fabrication of these Sub-Station Structures is done from latticed angles, Pipes, Plates and other such components. The galvanize consultant in India – Tanya Galvanizers ensures you with the best of the substation structures that can deliver safe and secured solutions for a long period.

Planned to be used interchangeably, the sub-station structures and switch yard structures work differently. For more information, switchyard Structure is generally applied for the assembly of switches, buses and auxiliary equipment, power circuit breakers, which are used to collect power from the generators of power plant and distribute to the transmission line at a load point. The transmission lines known as the power lines have a minimum of 66KV or above. Protection of substation equipments is the main aim of these transmissions Line Sub-Station Structures where shield wires may also used for communications.

Tanya Galvanizers uses the below mentioned raw materials for their substation structures:

- Aluminum Sheets

- Structural Forms – Angles, Channels, Beam, Plates, Flats, Rounds

- Zinc

- Primers

- Paints

Once the raw materials have been converted to a finished product, the supply is carried on with the finish of Hot Dip Galvanized, Primer coated, Enameled paint coated OR Epoxy paint coated. In addition, Tanya Galvanization adheres to inspection wherein a simple physical and laboratory tests is conducted on the random selected samples with the following steps as per the requirements:

- Visual Check Test

- Thickness of zinc coating Test as per IS-6745/IS-4759/IS-3203

- Adhesion Test as per IS-2629

- Uniformity of Zinc coatings Test as per IS-2633

Thus, providing best quality products, Tanya galvanizers renders these solutions to the power plants, cooling tower manufacturers, Railways, Refinery Projects, Fertilizer Industries, Cement Factories, Petrochemical Projects and many other large scale of industrial units. For more information visit: http://www.galvanizers.co.in/sub-station-structures.html