The ultimate search to find the best cable tray earthing manufacturers in Vadodara ends here at Tanya Galvanizers. We are a renowned and trusted name in the industry, serving all major galvanization work and cable tray earthing. Being in the market for decades, we understand the importance of the work and hence provide full-fledged assistance, which increases the product’s durability.

Whenever installation work demands the assistance of qualified personnel who have experience in serving established cable tray systems, there will be a high demand for cable trays. This is because it is highly recommended that the equipment grounding conductor (EGC) be used. The location where these cable tray systems are installed is unrestricted; for them, the team has designed a specific type of cable tray. These cable trays are EMI/RFI protected and are available with us.

While working on electrical products where the protection plays a sensitive role, there is a demand to have these electronics in the cable tray from external electric and magnetic fields. So, it is where these trays are entirely enclosed. The trays are built and tested to meet EMI standards. Further, these trays are covered with gaskets at the time when they are built. Cable Trays with solid bottoms and cable tray covers both provide some protection.

All About Cable Tray Earthing.

We may have heard about cable trays, but we will be discussing how they benefit earthing. A cable tray system is used in building electrical wiring, which helps support the insulated electrical wires. These wires are used in multiple areas like power distribution, control, and communication. Other uses of these cable trays are considered for commercial and industrial construction. It is an alternative method that assists in open wiring or electric conduit systems.

When we use the cable tray, which is required for power grounding, the team undergoes a thorough check. If it is not appropriate, as per NEC Section 318-7, there will be a lot of compromises in terms of signal and communication circuits that operate at low energy levels. But with the help of a grounded cable tray, there will be a requirement for lightning protection, noise, and electromagnetic interference.

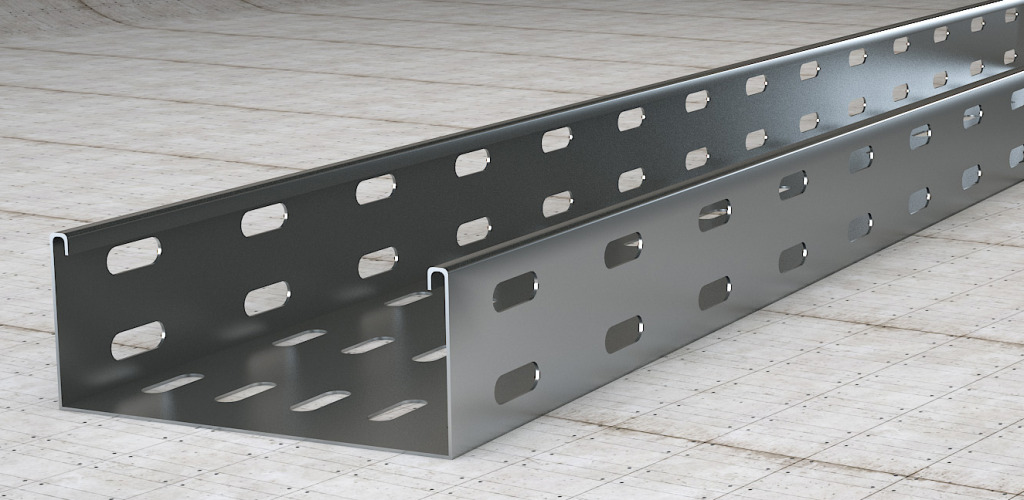

The common materials used for cable trays are galvanized steel, stainless steel, aluminium, and glass-fibre reinforced plastic. The material for a particular application is selected based on its intended usage.

Defining Cable Tray for Earthing?

A cable tray is a material used as the equipment grounding conductor (EGC) for any installation process. Here, a team of qualified staff installs the cable tray system. No specific restriction is required when installing a cable tray system. These cable trays are commonly used for cable management in construction projects for commercial and industrial buildings. They are meant to be used as an alternative for open wiring or electrical conduit systems.

Use of Cable Tray for Earthing.

The cable tray for earthing is used globally and in different industries. Some of the uses where these cable trays for earthing are used more are,

(1) The ground network where the building is constructed, and there is an access use of metal parts. Beams, metal frames or devices connect these metal parts. All these connected parts deliver a commitment to the equipment of the ground network.

(2) Manufacturers intend and demand to meet their specific requirements, so we recommend installing these cable tray systems beneath the ground every 50-60 feet.

(3) The cable trays installed on the ground have good bonding as they maintain a low potential for the ground. This reduces external electrical and magnetic disturbances and provides a continuous way that helps the currents stay in the best possible way without much damage.

Why Tanya Galvanizers?

We at Tanya Galvanizers understand the market and help meet the clients’ requirements while providing long-lasting cable trays for earthing. As we have been in the industry for quite a long time, we adhere to following mandatory standards and help understand the clients about selecting the best product required during the project. Hence, we are the Best Cable Tray Earthing Manufacturers in Vadodara. For further discussion and details, please feel free to contact us.