Every Highway, Express way and all safe roads should have Crash Barriers. The best way to make our roads sturdy and durable is to have galvanized the Barriers. At the very outset at the planning of highways, private roads and for that matter any road or pathway constructions should make this safety featured as a top priority. These are specifically constructed to prevent any accidents from happening on the roads. When integrated in the initial stages of planning, will enable to bring costs down quite drastically and in the long run with such solid constructions the maintenance of such roads is very low when compared to the expenses that are incurred at the present time, with this easy to implement and an important safety measure which is the need of the country at this time when many people having at least 2 vehicles per house hold.

Safe Application, Affordable and Cost Effective Solution

The cost implications are reduced for all the sectors, due to the durability of the roads, low cost of maintaining with fewer resources required carrying out checks and due to the toughness of the galvanised barriers the public will get a good cost effective service, in the unfortunate situation of accidents which do happen due to various reasons. With the roads being used by more vehicles than ever before a robust safety system needs to be implemented. With the increase of traffic on all roads a continuous enduring system of road safety measure needs to be the norm as part of building a better infrastructure. Also Airports, racing track, mines, chemical plants, railway crossings, and around water bodies are some of the places where this material can be used effectively. A onetime strengthen road reinforcement with zinc/iron which forms with the underlying steel, will give sublime smashed range impenetrability due to its thick significant layer. They serve as barriers for protection on all roads especially in mountainous roads since it prevents the vehicles from falling off high cliffs and on sharp turns on a semi-circular route.

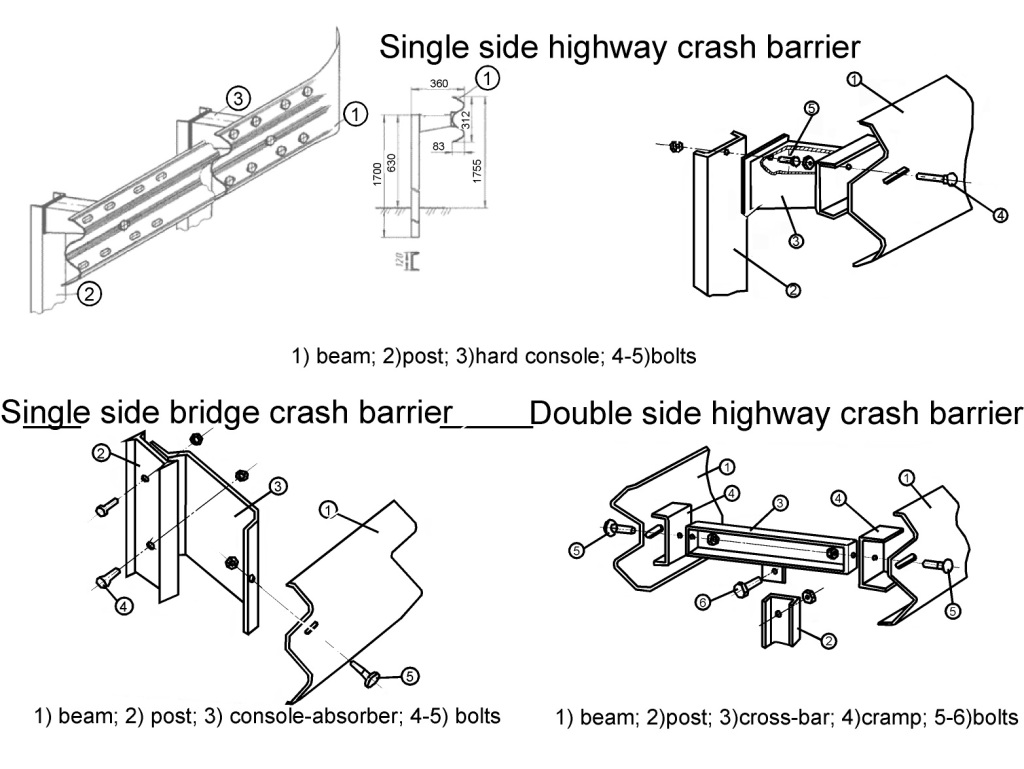

There are different kinds of Crash Barriers and a recent example is of a metal crash beam barrier which is available in the form of railings, so that you can implement it as rail guards for security purposes. Crash barriers are excellent and a worthwhile investment in the building of good durable protective and also as a defence mechanisms on roads. These prevention methods utilized, have significantly helped reduce the incidence of accidents happening in the country since its introduction in the market.

Tanya Galvanizers are in the fore front for manufacturing a wide range of Crash Barriers, with the latest methodology of Galvanizing materials that will revolution the way we make long lasting and safe roads and using material that meet the requirements of the high standards of today’s progressive and flourishing India.