Construction of a building involves three major engineering feats that include civil, mechanical and electrical works. While implementing electrical wiring in a building there is lot of things that needs to be taken care of. Cable management happens to be one of the most essential and integral part of electrical wiring of a building. Perfection in the routing of the electrical wires is essential in order for them to function properly. That is why it becomes important to use certain products that will enable safer environment for wires and people at the same time. Cable trays are one of the materials required for ensuring safety in a building.

What are Cable Trays?

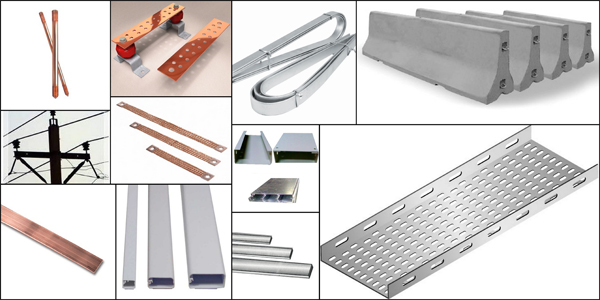

Cable trays are quite commonly used these days to hold courses, wires and cables safely inside a sky scrapper or a high rise. It is a construction material that has some major benefits. Cable trays are used for supporting insulated electrical cables and wires that are meant for communication and distribution. It also happens to be one of the most used products to be installed in industrial and commercial setups in order to provide an alternative for the open conduit and wiring system. Generally manufacturers of cable tray design them in such a way that they can easily adapt sudden changes in places where it is anticipated to have wiring adjustments. Cable trays are available in different types and it is always best to choose galvanized cable trays as it offer better safety.

When you are planning to implement galvanized cable tray you must know what the benefits you can get from these products are. Well there are actually more benefits of this product than you actually are aware of. So let us take a quick look at them:

Affordability – Cable trays are quite affordable than any other means of protecting the cables and wires. Especially in industrial constructions budget plays an important role. In many cases industrial machines are run on corrosive byproducts that can cause damage to the cable and wires and incur heavy cost in replacing the wiring system. Galvanized cable trays protect the wires from these chemicals and other harmful by products.

It is quite a reliable product – The usage of galvanized Cable trays offer great reliability. They are very durable and can last long. Galvanization offers protection from damage and thus the wires and cables last for years.

It has great adaptability – Since the cable trays are designed for providing safety and a storage system they can fit into any industrial construction. The universal design enables this adaptability on any system.

Safety quotient is high – Cable trays with galvanization are the most effective and safety way of protecting wires and cables. It does not expose the wires to hazardous and keeps them safe from any damage.

Low maintenance – The services for galvanizing cable trays are really low. Maintenance is easy and since these trays are made from galvanized steel there remains no question of corrosion.

Usage of cable trays in Industrial complexes

Galvanized cable trays are most essentially used in industrial constructions. It is imperative to use galvanized cable trays in order to avoid any mishap. So choose the best in the market and get sorted for a lifetime.

Visit: www.galvanizers.co.in/cable-trays.html for more information.