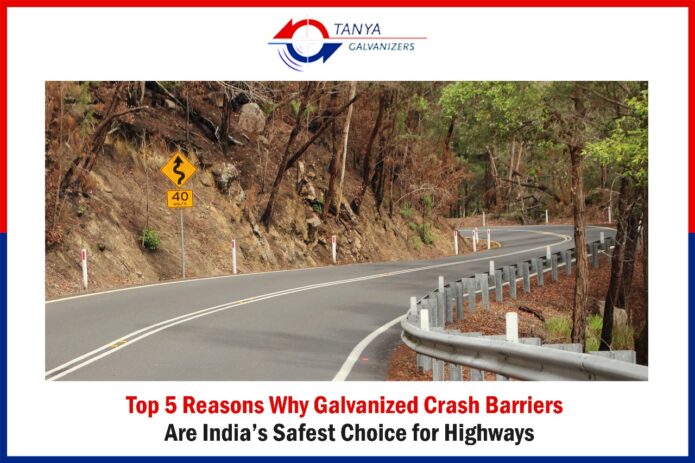

Every time you drive along a highway, the sturdy metal barriers lining the road silently safeguard lives. These are crash barriers — a crucial part of modern road infrastructure designed to prevent accidents and minimize damage during collisions. Behind their strength lies a powerful technology: galvanisation.

As one of the leading crash barrier manufacturers and galvanizers in India, Tanya Galvanizers has been instrumental in building safer highways through high-quality galvanized crash barriers that combine engineering precision with proven corrosion protection.

Let’s explore the top five reasons why Tanya Galvanisers’ crash barriers are India’s safest choice for highways.

1. Superior Protection with Hot Dip Galvanization

The strength of a crash barrier depends not only on the steel but also on its ability to withstand environmental wear and tear. Tanya Galvanizers uses hot dip galvanizing technology to coat steel barriers with molten zinc at 450°C.

This process creates a strong metallurgical bond, offering:

- Complete protection against rust, moisture, and pollutants.

- Longer lifespan, even in coastal or high-humidity regions.

- Reduced maintenance costs over decades of use.

By partnering with one of the most experienced galvanizers in India, highway contractors and government bodies ensure their crash barriers remain strong and corrosion-free for years.

2. Engineered for Maximum Road Safety

Every crash barrier manufactured at Tanya Galvanizers is designed following MORTH (Ministry of Road Transport and Highways) and IRC (Indian Roads Congress) standards.

Our barriers undergo rigorous testing to ensure they can absorb impact efficiently and safely redirect vehicles back onto the roadway.

Key benefits include:

- Reduced vehicle rollover risks.

- Enhanced safety during high-speed collisions.

- Consistent performance across all weather conditions.

With road accidents being a major concern in India, our galvanized crash barriers serve as the first line of defence in protecting both passengers and infrastructure.

3. Unmatched Durability and Longevity

Tanya Galvanizers’ crash barriers are built to last. Thanks to high-quality galvanization and precision manufacturing, these barriers maintain their integrity even after years of exposure to harsh conditions.

Why do they last longer?

- Uniform zinc coating ensures 360° protection.

- Resistant to chemical corrosion and abrasion.

- Effective performance in both rural and urban installations.

Our crash barrier manufacturers use advanced galvanizing tanks and automated quality checks to guarantee consistent coating thickness and adhesion — ensuring dependable safety across India’s roads and bridges.

4. Sustainable and Cost-Effective Solution

Sustainability is at the core of Tanya Galvanizers’ production process. Hot dip galvanization is eco-friendly, uses recyclable materials, and reduces the need for frequent replacements.

Advantages for infrastructure planners:

- Lower lifetime cost compared to painted or untreated steel.

- Reduced carbon footprint due to less maintenance and waste.

- Long-term savings for government and private contractors.

This makes our galvanized crash barriers not only safe but also economically and environmentally responsible — a smart choice for modern road safety projects.

5. Expertise, Experience, and Trust

With decades of expertise in galvanising steel for critical applications, Tanya Galvanizers has established itself as one of the top galvanizers in India. Our reputation is built on precision, reliability, and commitment to quality.

We serve national highway projects, bridge constructions, and industrial roadways — providing barriers that meet both international and Indian safety standards.

Our clients trust us because we deliver:

- Proven performance on large-scale infrastructure projects.

- Custom galvanizing services based on project requirements.

- Timely delivery and consistent quality assurance.

India’s growing road network demands safety solutions that last. Galvanized crash barriers from Tanya Galvanizers deliver the perfect balance of durability, strength, and sustainability. As trusted crash barrier manufacturers and galvanizers in India, we combine cutting-edge technology with decades of expertise to make highways safer for everyone.

Contact Tanya Galvanizers today to discuss your project needs and discover how our galvanized solutions can enhance road safety for generations to come.

FAQs

Q1: Why are galvanized crash barriers better than painted ones?

A: Galvanized barriers offer superior corrosion resistance, longer lifespan, and reduced maintenance compared to painted steel, making them more reliable for highways.

Q2: How long do galvanized crash barriers last?

A: With proper galvanization, Tanya Galvanizers’ crash barriers can last up to 50 years depending on environmental conditions.

Q3: Are these barriers suitable for coastal or high-humidity areas?

A: Yes. The zinc coating from hot dip galvanizing prevents rust, making them ideal for coastal, humid, or industrial zones.

Q4: What standards do Tanya Galvanizers’ crash barriers meet?

A: All our barriers adhere to MORTH and IRC standards, ensuring optimal performance and safety.