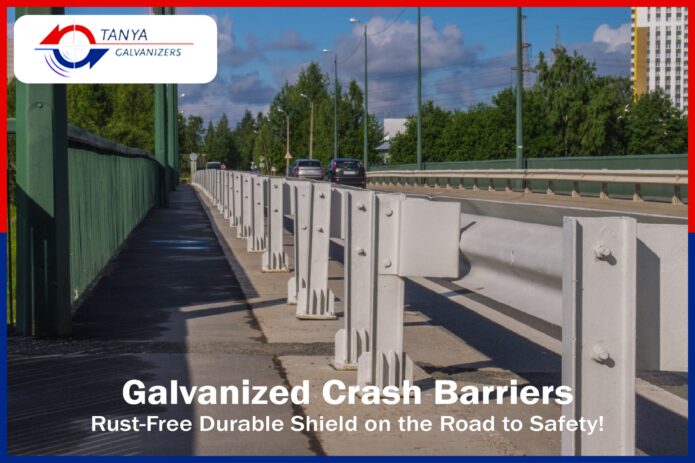

As individuals, we need to ensure that road safety measures are taken with high priority so that there is no loss to the lives of any people. One of the initiatives considered for road safety is having galvanized crash barriers that remain rust-free. The most common crash barriers on busy roads are metal beam crash barriers or guardrails. The design of these barriers is in such a form that provides accurate protection to vehicle occupants during traffic accidents. However, these metal beams undergo a proper galvanisation process before getting installed at the site. It is extremely affordable and comes with a top-notch hot-dip zinc coating.

Using the proper approach of galvanization, the barriers will remain rust-free, l will have considerably long durability, and it will look like a brand new deployment for an extended period. Since these crash barriers are integral to road safety measures, we adhere to the following standards and guidelines when processing work for the road crash barrier galvanization.

It is always noticed that roadside accidents occur only when there is ignorance and a casual approach while driving vehicles. The moment leads to life-threatening events, and people may face the consequences. Thus, sign boards must be installed on the roadsides to avoid such events and be more careful. With a need for crash barriers, another thing that is taken into consideration is proper calculations that determine the appropriate requirements, such as the size, length, speed, and volume of the traffic. The perfect place for installing barriers is at bridge ends, crossroads, deep slopes, poles, or areas that may pose a danger.

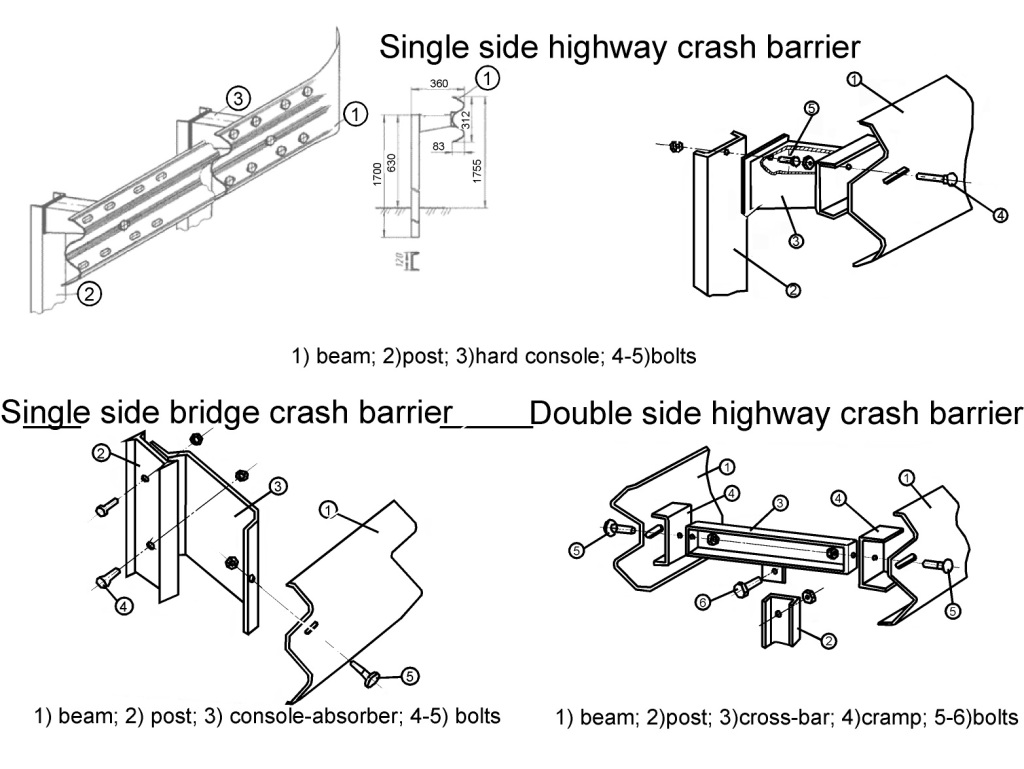

Different Types of Crash Barriers

There are multiple types of crash barriers which are used. The demand for galvanized barriers depends on the core requirements. Once we know which kind of crash barrier is required, we proceed with galvanization work by providing galvanized steels. The list of the kinds of barriers are listed below,

– Road Signage and Markings

– Synergy with Road Lighting

– Traffic Calming Measures

– Emergency and Breakdown Lanes

Are you Looking for Reliable Galvanization Service Providers for Crash Barriers?

We are the leading and renowned name in the industry, providing all significant galvanisation types of work. When it comes to road safety measures, proper galvanization is required. Hence, you can contact us, and we assure you that with correct adherence to the standards and process, we will provide accurate Galvanization services.