With the development of modern roads and people buying cars and other vehicles for the convenience of their life one of the major issues that they face nowadays is road safety. Yes, road safety is of prime importance these days as accidents are getting fatal. Safe driving is being promoted everywhere in the world and the governments around the world are taking various measures to minimise accidents and help people to survive the fatality of the accidents. One of the most common yet very important road safety measures that have become an indispensible part is the galvanized crash barrier.

About crash barrier

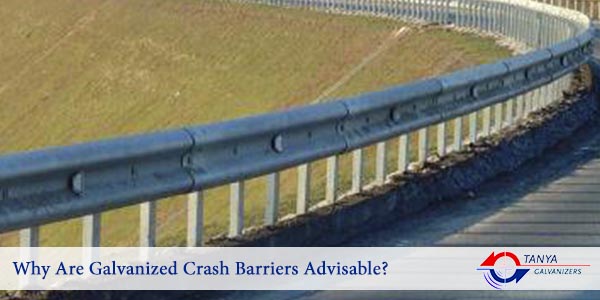

Also know as traffic barriers these crash barriers can actually save lives if an accident happens. These barriers have been designed to restrict fatal collision of speeding cars with boulders, walls, building and any other hazardous thing beside the road. The galvanized crash barriers are placed on the roads strategically in order to curb the speed of a vehicle and make it fall beside the road. Understanding its importance on the roads crash barriers are installed on all major roads especially on highways where people at times speed up their vehicles. These barriers not only stop fatal accidents but also help in creating traffic lanes for the vehicles to move in order.

Read more: Crash Barrier | Industrial Crash Barrier | Galvanized Crash Barrier

Why galvanized?

This is an important question that may come across your mind. Well as we all know galvanizing crash barriers will only make them strong and durable. Galvanized steel is used for making crash barriers especially those which are installed on highways. High quality and high durable metal crash barriers are quite commonly seen on the highways and in sharp turn where there are chances of accidents. Hot Dip galvanizing process is used for these barriers to make them durable and last long even after resisting fatal accidents.

Where can you get the best crash barriers?

You might wonder that crash barriers are only used on roads and highways to avoid accidents and fall off. But these life savers have other uses too and you can use them at your own convenience. Road contractors especially need these barriers to mark the area of their work zones on the roads. So if you are a road contractor or into structural engineering and looking for the best galvanized crash barriers then you should contact Tanya Galvanizers who offers the best quality products in the market. Located in India this company offers their products and services to a wide range of clientele all over India. The company consistently produces galvanized crash barriers that are used in different places. They can also customize products for your convenience.

With years of experience and technical expertise in Hot Dip Galvanizing, Tanya Galvanizers have paved their way to success by satisfying a wide range of clientele from different types of industries. Their good reputation and the top class products make it easier for the prospective buyers to have the trust to get the best service. So when you are in need of galvanizing crash barriers you know where to go.

Tanya Galvanizers: Best Galvanized Crash Barriers Suppliers – read more

Click here for more information or Contact us: info@galvanizers.co.in or Call +91 80008 42648.